Select the equipment you want to explore and press the + button to view our product in 360° with the equipment you choose.

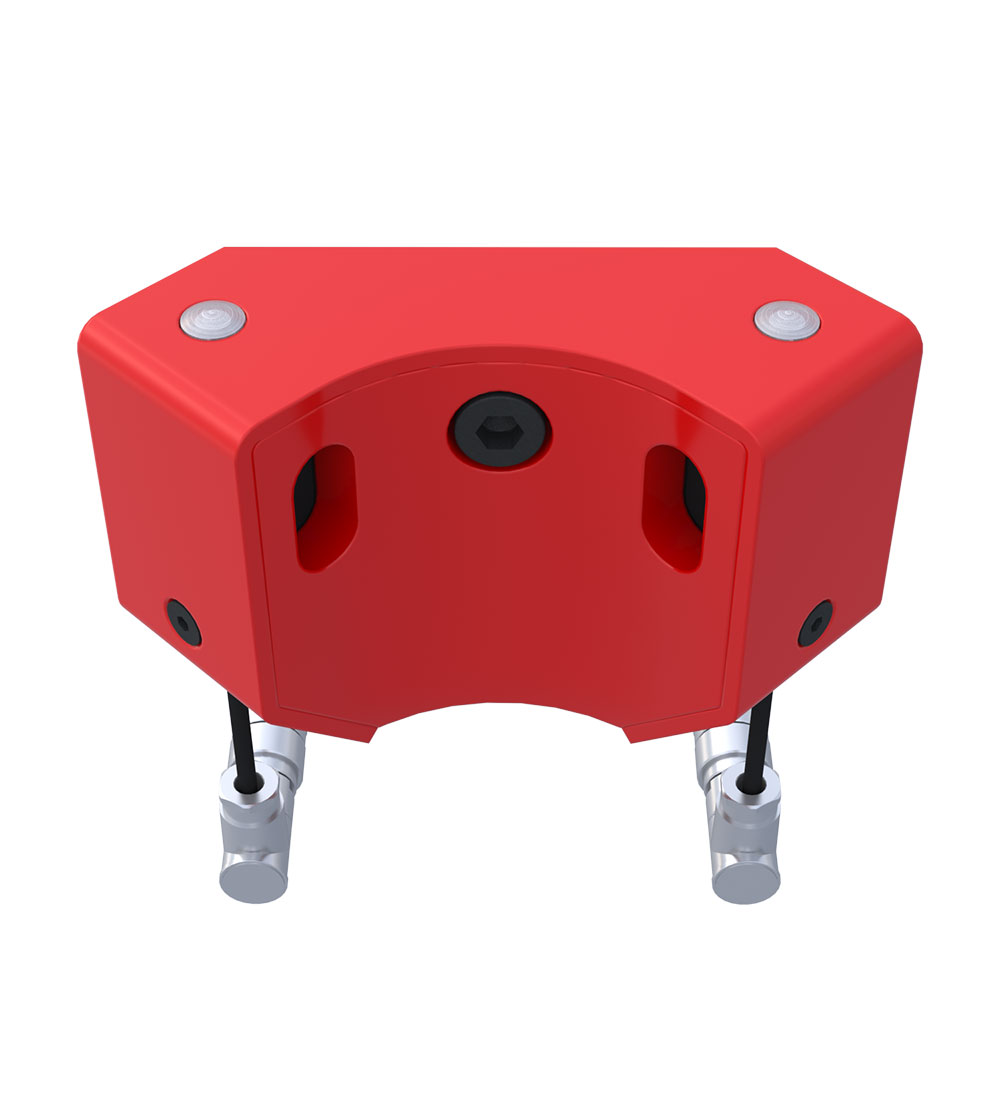

MDC 100 Base

MDC 100 BASE

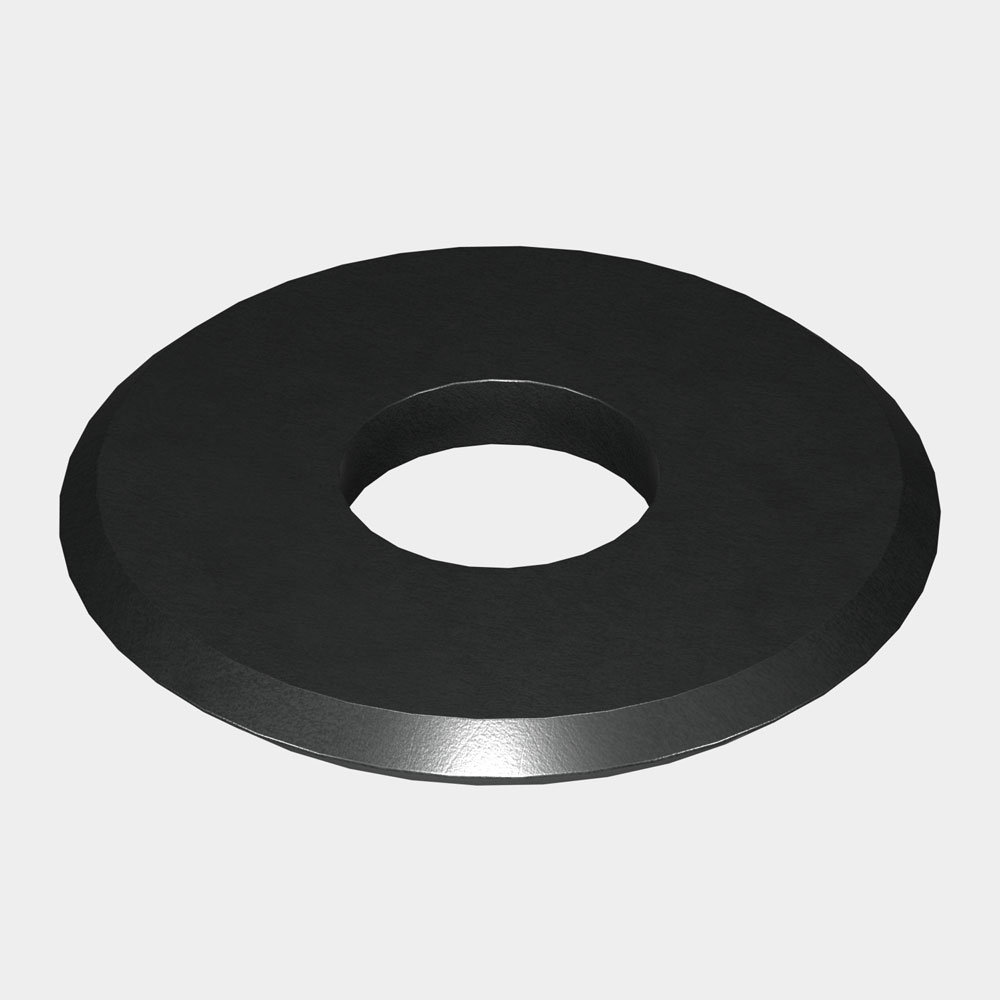

MDC 100 Base performs the current nozzle and nozzle replacement process.

MDC 100 Base automates the current nozzle and nozzle replacement process, eliminating operator-related errors and delays. It is 82% faster than manually replacing the current nozzle and nozzle.

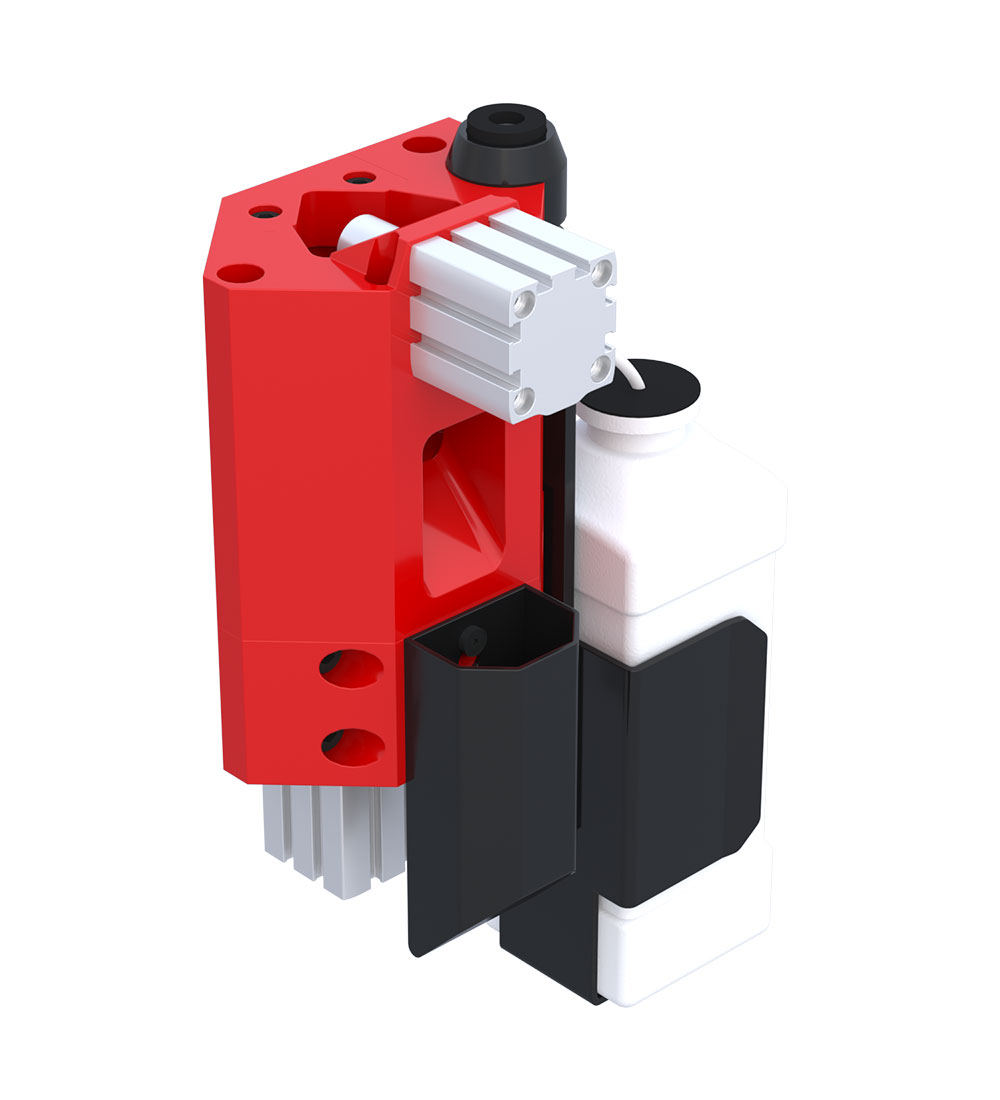

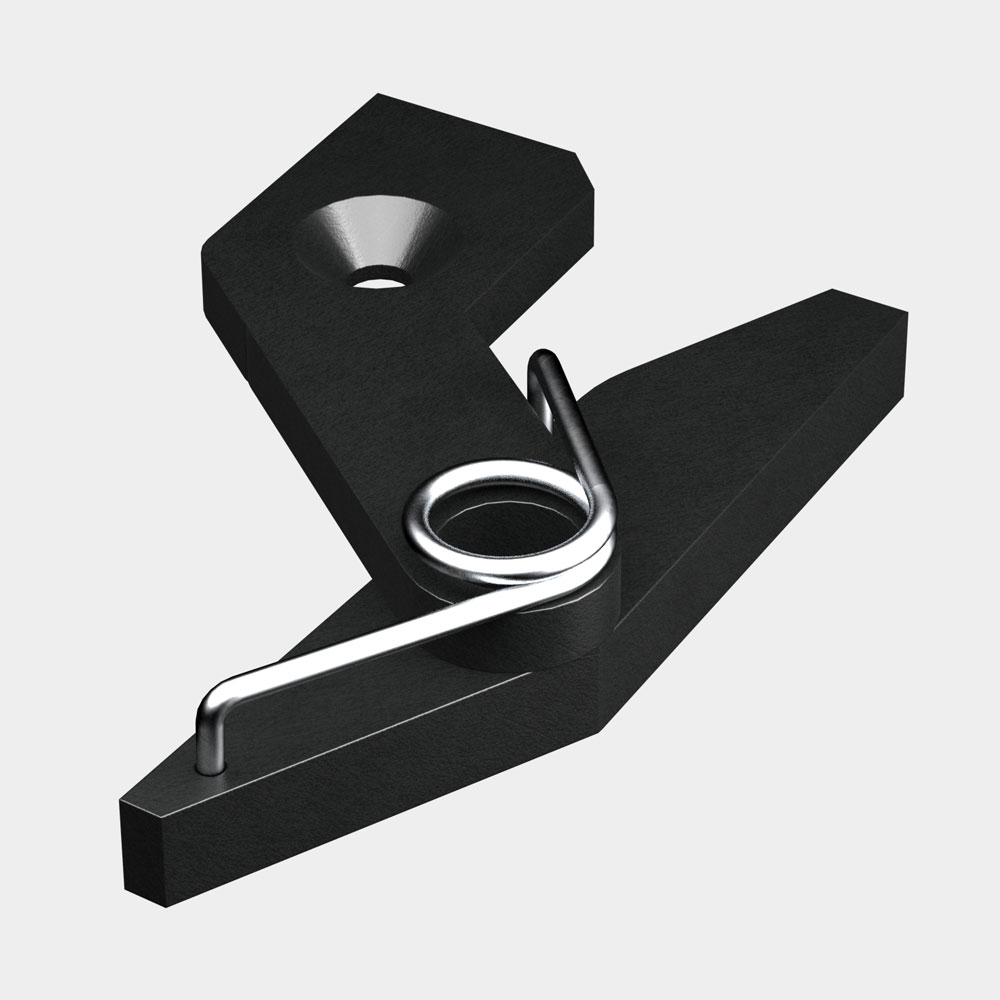

K: Wire Cutting and Current Nozzle Cleaning Unit

N: Nozzle Cleaning and Spray Unit

O: Nozzle and Current Nozzle Detection Sensors

MDC 100 Base delivers superior performance in current nozzle and nozzle replacement tasks. This device automates the process of current nozzle and nozzle replacement, eliminating operator-related errors and delays.

In manual current nozzle and nozzle replacement processes, errors can occur depending on the attention and experience of the operators, negatively affecting process efficiency. MDC 100 Base is designed to completely eliminate such errors. With its automated systems, it completes tasks in 40 seconds and error-free, minimizing operator intervention.

Furthermore, the automatic operation capacity of MDC 100 Base significantly reduces processing times. Compared to manual operations, it performs 82% faster, resulting in significant time savings on the production line and enhancing overall efficiency.

With MDC 100 Base, the risk of operator errors is reduced while contributing to smoother and uninterrupted progress of the production process. Thanks to these features, MDC 100 Base stands out as a reliable and effective option in industrial automation solutions.

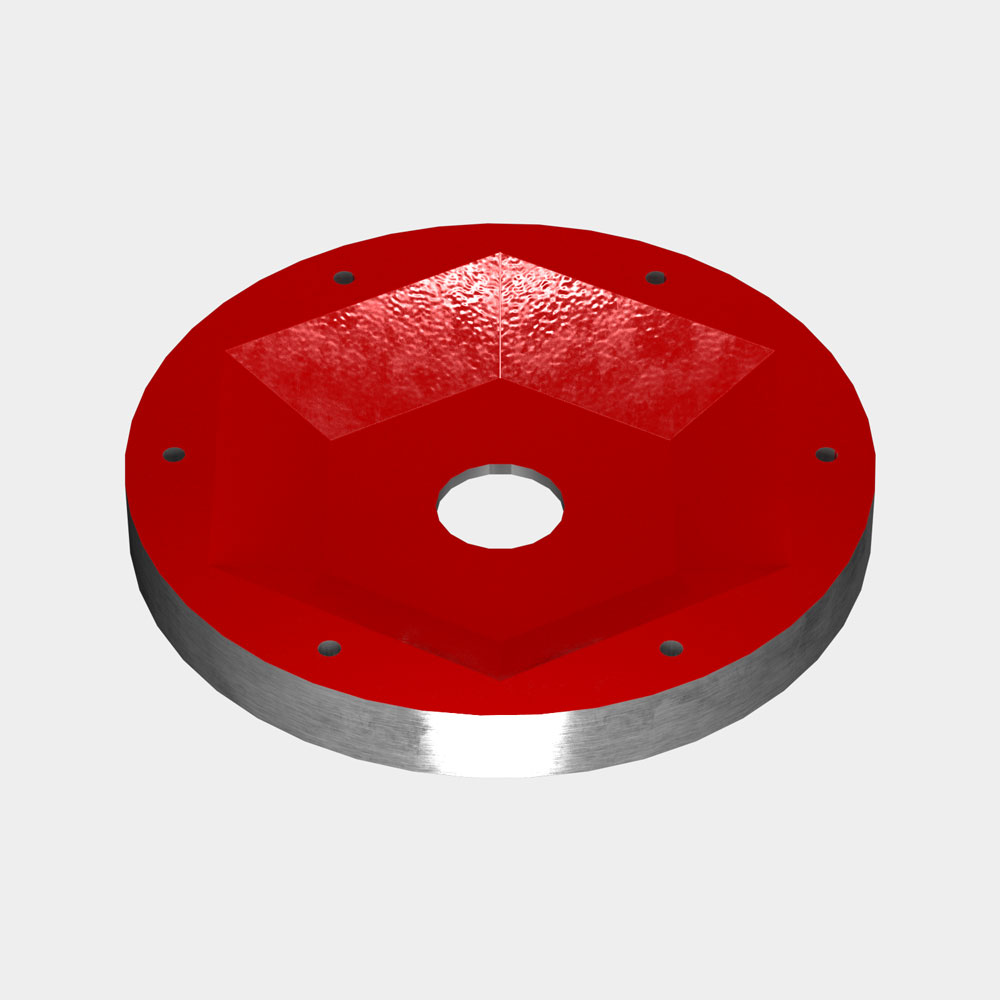

| 1 | Dimensions(MDC-100-Base-KNO) | 57mmx405mmx520mm |

|---|---|---|

| 2 | Dimensions (MDC-100-Base-K) | 1057mmx317mmx380mm |

| 3 | Dimensions(MDC-100-Base-N) | 1057mmx320mmx520mm |

| 4 | Dimensions(MDC-100-Base-O | 1057mmx225mmx424mm |

| 5 | Dimensions(MDC-100-Base) | 1057mmx225mmx380mm |

| 6 | Weight | 72KG |